Companies in Focus: Big Akwa Aims to Double Sweden’s Food Fish Production

We continue to highlight companies in northern Sweden in our article series Companies in Focus, where we share stories of how ideas become real, sustainable solutions. This time, we meet Big Akwa, which through large-scale land-based fish farming and industrial symbiosis aims to more than double Sweden's food fish production – while strengthening the country's food supply in a resource-efficient way.

--------

Big Akwa Aims to Double Sweden's Food Fish Production

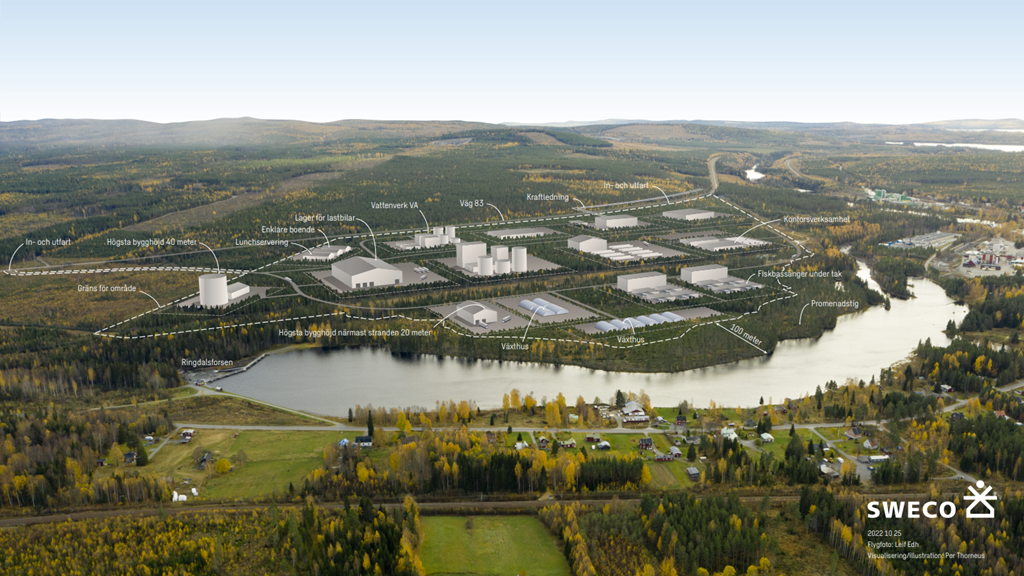

Big Akwa has taken another major step toward establishing Sweden's most advanced land-based fish farm. Following this summer's announcement of a 25-year environmental permit to produce 6,000 tonnes of rainbow trout per year, detailed planning of the facility in Alby, Ånge Municipality, is now underway. This marks the beginning of a multi-billion-krona project that could fundamentally transform Sweden's food fish production.

“These are two decisive milestones. With the environmental permit secured and the site confirmed, we can begin designing the entire facility – from the building layout to how the fish will be processed on site,” says Daniel Brännström, CTO of Big Akwa.

Today, around 9,000 tonnes of food fish are produced in Sweden by some thirty companies. Big Akwa's facility alone would increase national production by two-thirds and account for 20 percent of Sweden's total consumption, making it the largest project of its kind in the country.

“We are not accustomed to this scale in Sweden. But if we are serious about reducing import dependency, we need to increase domestic production. This is a sustainable and resource-efficient way of doing that,” says Daniel Brännström.

Industrial Symbiosis – the Foundation of the Model

The project is based on a circular, integrated approach in which the fish farm will collaborate with other operations in Alby, including planned production of green hydrogen and sustainable aviation fuel (Power-to-X). This creates mutually reinforcing resource flows:

- The fish farm's carbon dioxide emissions are sufficient to supply a ten-hectare greenhouse.

- Sludge and plant residues can be converted into biogas or fertiliser.

- Treatment processes are integrated so that both the fish farm and nearby industries benefit from more efficient and stable operations.

- Hydrogen production generates oxygen – a key resource for large-scale RAS (recirculating aquaculture systems).

- Water is drawn from the Ljungan River, treated, and returned at high quality.

The symbiosis is also central to the project's climate benefits.

“Without scaling up, it is not possible to manage residual products effectively. It is only at this level that everything falls into place and delivers real system-wide benefits,” says Daniel.

Built on Proven Technology – Double the Scale

Big Akwa builds on two existing reference facilities in Denmark and Finland, producing 2,500 and 3,000 tonnes respectively. The Alby facility will essentially replicate and double the Finnish model, with local adaptations and significantly stronger circular flows than in previous projects.

Once operational, Big Akwa will slaughter and process the fish on site. Weekly production will amount to approximately 120 tonnes of rainbow trout – or around 30,000 fish weighing between 1 and 4 kilos.

The company holds an option on the land and plans to acquire it in 2026. The goal is to complete the detailed building design during 2026–2027 and begin construction the following year. Operations are scheduled to begin in 2028.

Industry interest is strong. Technology and service providers – including companies in energy, construction, and water treatment – are keen to participate in the project.

“We have noticed a clear shift since the permit was approved. Many see the value of being part of something that both strengthens Sweden's food supply and demonstrates how circular industrial systems can function in practice.”

Click here to read more about Big Akwa!

Foto: Sweco/Big Akwa