Inpipe's Green Innovation Can Solve the World's Ticking Environmental Time Bombs

Since the beginning in 1986, the Vilhelmina company Inpipe's trenchless innovation has renovated drains and pipes over the entire world and contributed to large quantities of reduced carbon dioxide emissions.

The next unique solution is now being launched – a liner for pipe renovation free of the solvents styrene and Bisphenol A.

"In this manner we are contributing still more to a green conversion when it concerns the water and sewer systems of the future. There are ticking environmental time bombs across the entire world that must be addressed," says Rolf Näslund, Sales and Marketing Manager. It was in the Municipality of Vilhelmina where the inventor Vollmar Jonasson started the factory with its globally unique patent for fibreglass-reinforced polyester liners – a type of casing that is fed into a damaged or very old pipe and builds up a strong and flexible conduit after it hardens.

Since 1999, the Danish corporate group Arkil Holding A/S owned Inpipe Sweden AB, but in April 2021 it was announced that Björnvind Holding AB had acquired Inpipe. The current Managing Director of Inpipe, Nicklas Björnvind, is behind Björnvind Holding, and he has a very positive view of the future.

"We now have a still greater opportunity to own and influence the possibilities for the company's growth. We find ourselves in a very interesting phase this spring where we will be launching Inpipe Freeliner and we are projecting a quite substantial strengthening of our marketshare," says Nicklas.

Hundreds of metres per day

Back to Rolf, who actually grew up in Vilhelmina and started his new position around the end of the year when he left Svensk Bilprovning, where he had been the Sales Manager.

- I remember from my childhood when the factory was built and the hype that existed around Vollmar's invention.When I worked in London for a period of time at the beginning of the 2000s, I came across an Inpipe vehicle by coincidence that was performing a job in London's piping network and it was a proud feeling by a Vilhelmina boy I must say," states Rolf.

Rolf Näslund, Sales and Marketing Manger at Inpipe.

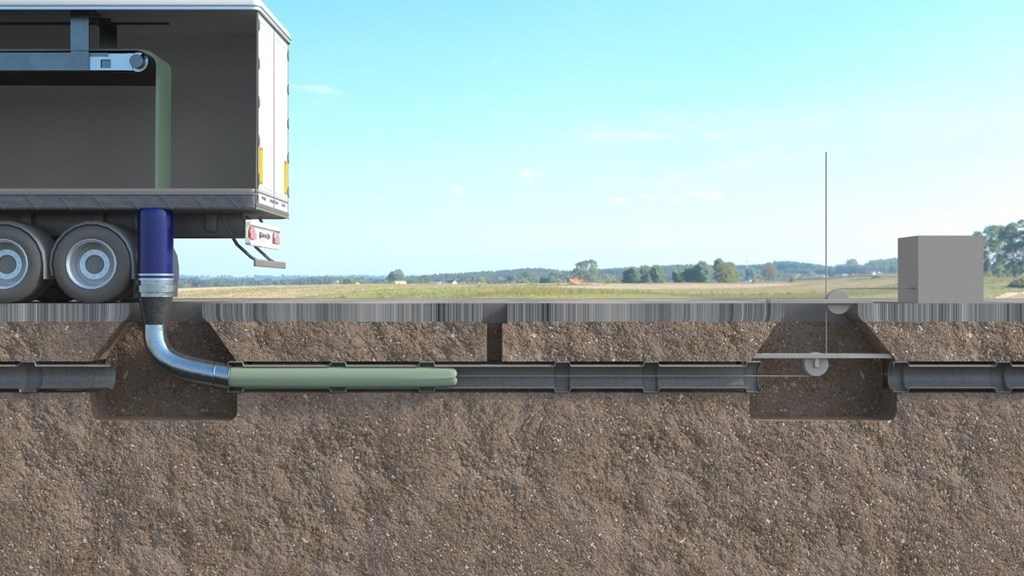

Today, Inpipe has concentrated its activities on development, manufacturing and sales and works in the global market with its trenchless solution. There is stiff competition today in the area of relining, but Inpipe's installation solution is unique. Two people can renovate several hundred metres of conduits per day without needing to excavate – everything is managed from inside an installation vehicle. Via a man hole, the liner is fed into a conduit that needs to be renovated, and when it is ready the liner is expanded and subsequently a light train with UV is sent in the same way. The liner is hardened in this manner and becomes sealed, strong and flexible in order to resist any possible movements in the ground.

"We make a thin and strong liner, which allows the maximum flow to be retained in the conduit. In addition, the liner expands in order for there to be minimal air gaps to the existing conduit. So no unwelcome water, soil or roots can permeate in and be transported," says Rolf.

Saved 18 million SEK

The traditional solution for renovating pipeline networks is to excavate, that is to dig up the conduits and lay new ones. The carbon dioxide emission is significant – to lay 100 metres of pipe four metres below ground level saves instead of excavating 28 tons of carbon dioxide. This is comparable with driving a vehicle 5.5 times around the earth, alternatively 18 years of normal vehicle driving. And this is without considering the costs this involves.

"Many people excavate purely by tradition and are not aware of this solution and precisely what enormous environmental gains it would involve, not to mention the pure cost savings for the customer," says Rolf.

In a recently completed job at Liljeholmen in Stockholm, NCC used Inpipe's solution. The task was not easy – the stone-laid conduit had very large dimensional changes and was difficult to access with a steep slope.The work took one day and Stockholm Vatten och Avfall [Stockholm Water and Waste] is calculated to have saved SEK 13–18 million by not excavating the section of a good 50 metres.

"There is nothing noteworthy about the time it took to do the work or the result, these are the numbers we are used to seeing. This technology is of great use to society and conserved both the environment and the wallet. The carbon dioxide that is involved with digging up the ground and transporting away the excavated soil is significant," says Rolf.

New product this summer

Inpipe has over the years cross-pollinated its Northern Swedish industriousness with Swiss high technology and developed a liner free of both styrene and Bisphenol A. The latter item is on the phase-out list of the Swedish Chemicals Agency.

"Increasingly higher and higher requirements are quite rightly being imposed by the regulatory codes and the customers. It involves both the environment and the working environment. Styrene secretes among other things a strong odour and we have previously solved this with a styrene-impermeable foil around the liner, but now we have a solution completely free of styrene. Bisphenol A has not been present in our products, but does occur in many other styrene-free solutions. That we have a product that is free of both items places us and the environment in an enormously good position," opines Rolf.

Inpipe has christened the product Inpipe Freeliner® and it is anticipated to be introduced to the market this spring. Inpipe Freeliner® is BASTA-registered, which involves them being able to substantiate that the product meets the BASTA criteria for properties concerning environmental and human health hazards.

"This means that we have an extremely strong stamp of quality on Inpipe Freeliner®. The solution has the exact same good properties as previously established with the toxin-free guarantee," says Rolf.

”The potential is enormous”

Many pipeline networks around the world has neared or passed their envisioned lifespan and now need measures in order to tackle the repairs. The need is on the verge of being enormous.

"I recently read a report that was done in the US and where it is calculated that 2 billion kilometres of new conduits need to be renovated. It appears to be the same in Japan, Australia and a number of other countries. We are holding talks right now with an American partner and hope to be able to enter their market and we currently are pursuing an offer for a new large project in New Zealand," says Rolf.

What in your opinion is the potential for your new product?

"I think the potential is enormous. We have in many ways a unique product and a new environmental solution to a gigantic environmental problem. Many people in leading positions unfortunately do not have any knowledge about what is possible to do and it is there where we need to make inroads. A politician probably thinks it is nicer to build new public baths than to invest in something beneath the ground, but it is here where the current politicians have an opportunity to do something for future generations," thinks Rolf.

New numbers in Sweden show that the need for investment in the water and sewer sector has increased to 23 billion per year, but in total only 16 billion is invested, an annual gap in fact of seven billion.

"Even though it is a neglected area, one need to bear in mind that 16 billion per year is being spent in Sweden, which says a bit about the challenges we are facing," says Rolf.

You are new to your position since the beginning of the year – how does it feel to work with these types of environment-improving issues?

"I have worked in many different industries but over time felt that I wished to be doing something that made a difference. When I was at Svensk Bilprovning, we contributed to saving lives through increased traffic safety and at Inpipe we have a solution that can really change the standard of living for people as well as improve the environment. We have long taken clean water and functioning sewers for granted, but the climate changes with droughts and heavy rainfall can have serious consequences if nothing is done about it," he says.